flow rate calculator 3d printer

Measuring the calibration cube. Posted April 25 2017 flow rate estimation.

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print

Set the wall count to 2.

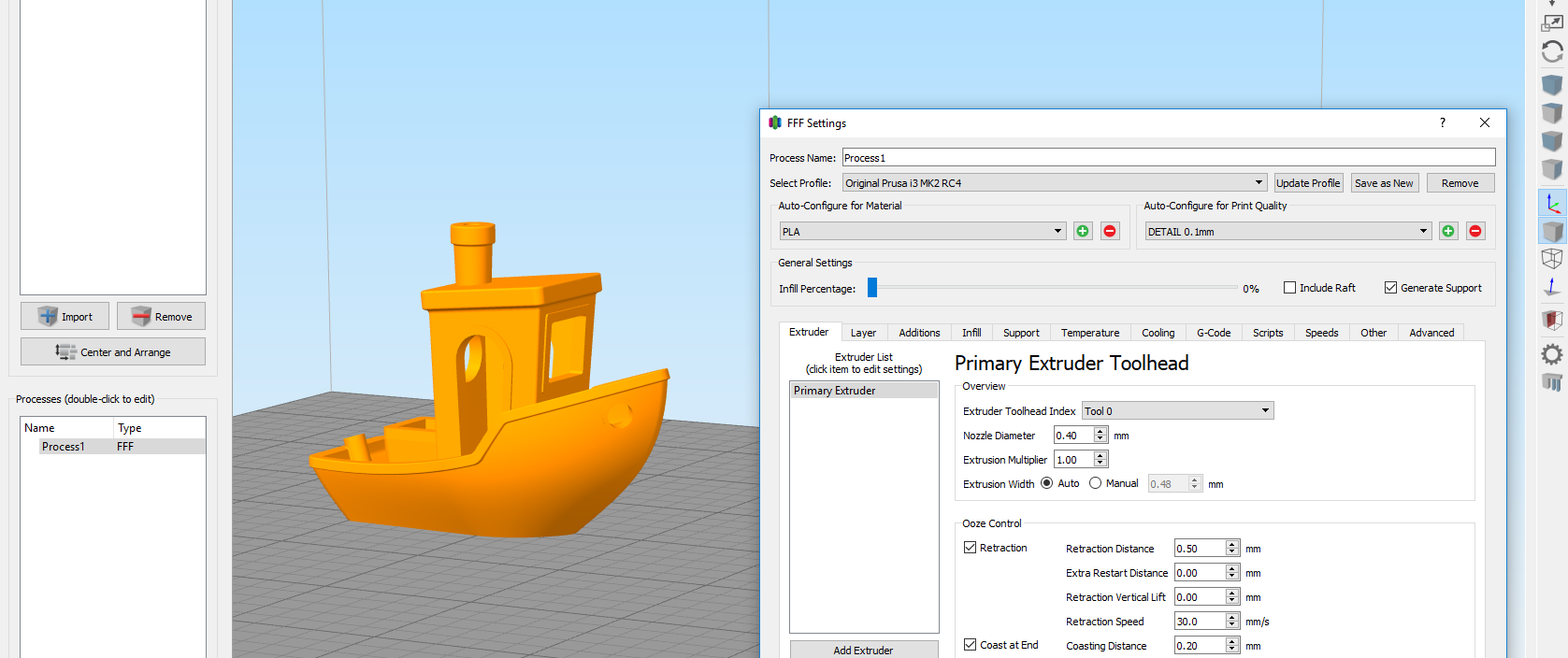

. Remember to reset the flow rate in the slicer to either 100 or 100 if the slicer uses a multiplier. The flow rate compensation factor is a percentage value that the printer multiplies with its current flow rate to calculate the effective flow rate it will use for the printing process. In this post we will learn about calibration of material flow rate in the 3D printers.

Lets assume that the max. This is typical for most printers as purchased. Extrussions speed is F600 then divide the 600 by 60 to get the speed mm this would be 10 mm second here.

This same calculation is used regardless of the axis. The flow rate also known as extrusion multiplier is a slicer setting that determines the amount of plastic a 3D printer will extrude. The printing parameters are.

With 100 flow rate the cube is oversized. Printing a 06mm track from a 04mm nozzle. Now from within the 3D slicer set bottom layers to 1.

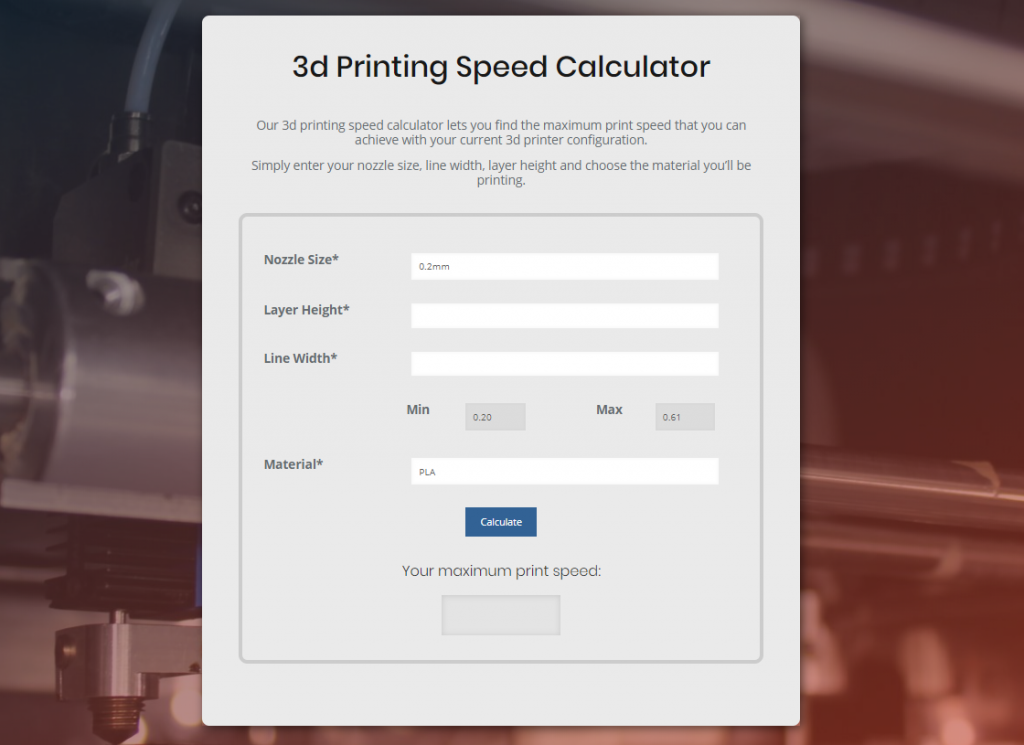

These calculators and resources will allow you to calibrate your printer for optimal results. Shout out to to Follow Media for pointing out that the layer height and extrusion width needs to be halved before entering into the formula the gu. Use the calculator below to find out your safe maximum flow rate.

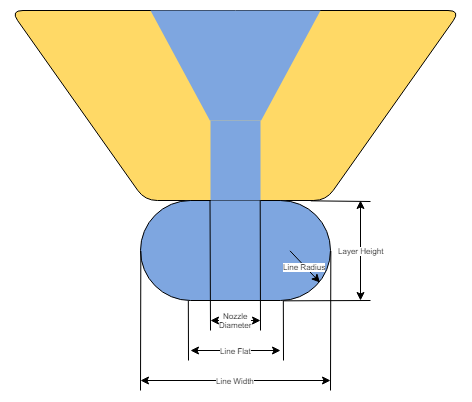

1 Reduce the measured rate 5 mm 3 s is a good amount to leave some headroom for hardware and filament variations. Click the three lines icon next to the search input and choose the All option to make advanced settings visible. Remember the width of the track is usually the same as the nozzle diameter although it is often better to print a wider track if you want improved mechanical performance eg.

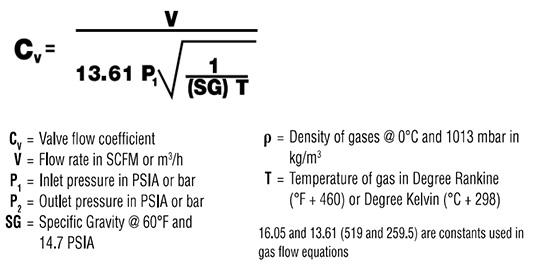

New Micro Step Rate. Flow Rate Calibration Guide 3DMaker Engineering Flow Rate Calibration Overview. Dear all i found that it is possible to calculate the flow rate FR by the following equation.

To correct this deviation we will. Remember the width of the track is usually the same as the nozzle diameter although it is often better to print a wider track if you want improved mechanical performance eg. Now we can use this.

Select the pane on the right the one with print settings. Simply enter your nozzle size line width layer height and choose the material youll be printing. Click the Custom button if you see it to switch the Print Settings to Custom Mode.

The default value for the flow rate is usually 100. FR Nozzle size mm x layer height mm x print speed mms mm3s. If you find our articles helpful and would like to help support the Make N Print website please visit the support us page for more information.

Max flow rate 10 pi 1715 2 2 10 314 175 2 175 2 2405 mm³ s. 3d Printing Speed Calculator Our 3d printing speed calculator lets you find the maximum print speed that you can achieve with your current 3d printer configuration. A volcano-type is closer to 20-30 mm 3 s whilst E3D claim 110 mm 3 s for their super volcano.

FR Nozzle size mm x layer height mm x print speed mms mm3s. This will all you to produce dimensionally accurate prints. Steps per milimeter The steps per millimeter stepsmm calculation is used to calibrate the X Y Z and E axis of your 3D printer.

New Steps Per mm. Is this something for a specific slicer or is polymer volume flow and filament speed an output that needs to be used in an equation for flow rates. 3D Printer calibration is critical to 3D printing accuracy.

Set the top layers to 0. Now that you have a safe maximum flow rate calculated you can convert this. I use an ender 5 plus which hasnt got an entry point for e steps when stock meaning I.

Alternatively please have a look at our affiliate links in the 3D Printing Deals and Coupons section. Current Micro Steps Rate. Multiply the speed in mms by the area of the cross-section of my 175mm filament 2405 to get the corresponding rate measured in mm 3 s.

It is necessary but not enough. In fact a high percentage of the 3D printing defects is related to. Using these settings the 3D printer figures out how fast to run the extruder motors to send enough filament for printing through the hotend.

Set infill to 0. A volcano-type is closer to 20-30mm 3 s whilst E3D claim 110mm 3 s for their super volcano. Nozzle of 040 mm width of layer 080 mm to create two outer layers and make the measurement more accurate and flow rate of 100.

Calibrating the flow rate will involve printing a test cube and measuring its walls to identify the actual flow rate compared to the flow rate value. Calibrating your flow rate extrusion multiplier will ensure you are getting the optimal volumetric flow from your hot end. A extrusion width identified in Step 52 b layer height2 c print speed.

Max flow rate Max extrusions speed pi filament diameter 2 2 Calculate the maximum flow rate. After this process mating parts should also fit together correctly. Nevertheless it is not clear because of in this equation the surface of the filament it is not taken into account.

How To Calibrate 3D Printer Flow Rate. Lets assume that we have a maximum flow rate of 1386 mm³ and we want to print with a layer height of 02 mm and a layer width of 048 mm. In the posts about E-step Setting we discussed on how to adjust the the length of filament that is pulled in by the extruderIt is one of the important settings for having a high quality 3D printing.

Printing a 06mm track from a 04mm nozzle. When using PLA with 100 flow rate recommended 90 we have obtained a measurement of 088 mm clearly oversized. Finally slice and export the cube to the SD card.

With a 04mm nozzle and a flow rate of 1 or 100 the thickness of a single wall should be 04mm. This is typical for most printers as purchased. Recommended maximum speed maximum flow rate layer height extrusion width to calculate the maximum printing speed.

If we know the maximum flow rate of the hot end we can use this formula.

Flow Rate Calibration Guide 3dmaker Engineering

Calculating Flow Rate For Your 3d Slicer Desiquintans Com Flow Slicer 3d Printing

How To Calculate Flow Rate Through A Valve Gems Sensors

Setting The Material Flow Rate Of Your 3d Printer Best Cheap 3d Printers

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

3d Print Speed How To Find The Optimal Speed For Reliable And Constant Print Quality

Calibration Of The Flow Rate Extrusion Multiplier Of Our 3d Printers Just One Important Step Youtube

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Flow Rate Calculator Advanced 3d Printing

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Calculating Iv Drips Rates Pharmacology Nursing Nursing School Survival Nursing School Studying

3d Print Speed How To Find The Optimal Speed For Reliable And Constant Print Quality

3d Print Speed How To Find The Optimal Speed For Reliable And Constant Print Quality

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print